Our History

Sturgeon's Mill From Past to Present

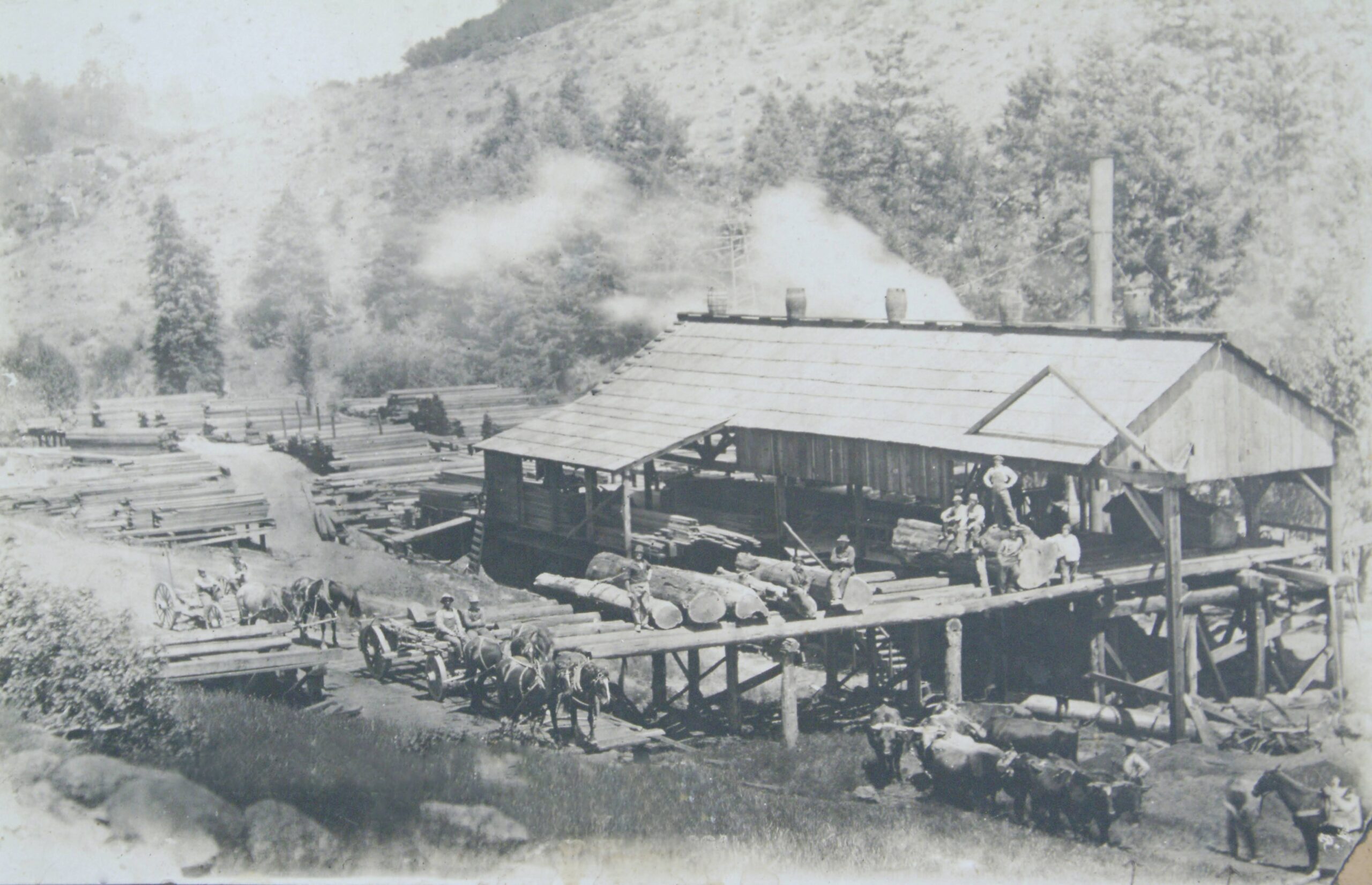

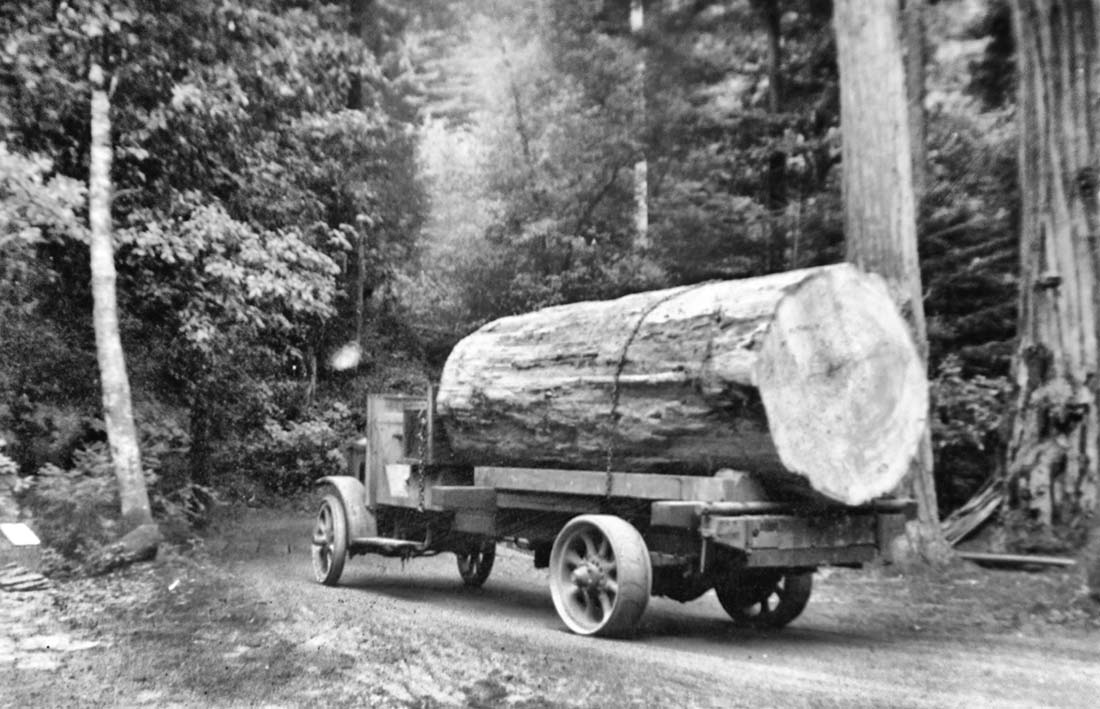

The technology of Sturgeon’s Mill dates to about 1865-70, only about 80 years after the start of the industrial revolution. In the early days, logs were pulled out of the woods with mules, oxen, and horses, then hauled to mills like this one. The development of the steam-powered donkey engine in 1883 began replacing oxen and greatly increased the production of lumber.

The arrival of the North Coast Railroad in 1877 opened the Russian River basin to a logging boom. Mills such as this mostly served the local market. Previously, lumber was shipped from dog holes (small safe ports where lumber hauling ships could dock) along the coast via sailing schooners to build and rebuild San Francisco.

Wade began sawmilling in Coleman Valley in 1914. Moving the mill in 1923 to Green Hill Road, he was joined with partners, Joe Donati and John Gonella. It used ox teams, horse teams, and machinery from the old Korbel (of champagne fame) mill in Guerneville. The Korbel mill dated back to the 1870s. In 1922 the log supply ran out in Coleman Valley and the mill was moved to its present location.

Steam donkey engines replaced the oxen in the logging operations at that time, but logs continued to arrive at this sawmill’s present location via beasts of burden with Teamster Mr. Craig driving a team of four mismatched horses.

Esther and Wade Sturgeon lived in a rustic log cabin across from the mill. They created a garden and pond and filled the area with exotic plants. Wade hybridized lilies and horticultural enthusiasts came from all over to admire their work. They were both friends of Luther Burbank.

The mill includes outbuildings; the recently restored mill office built over a live creek to conserve space; and a blacksmith shop equipped with old-time tools from Montgomery Ward and Sears-Roebuck.

As told in a documentary film, available for purchase at the registration desk, in 1942 Ralph Sturgeon (Wade’s son) and Analy High School friend Jim Henningsen formed a partnership in the mill with nothing more than a handshake and pooling of resources. They purchased the mill and leased the property from Wade Sturgeon. The operation would continue under their ownership until 1964.

The partners eventually acquired a 2000-acre tract of timber known as Bodega Rancho west of Occidental which supplied the mill with logs based on a plan of “sustainable cutting” which preserved the forest for the purpose indefinitely.

The mill provided lumber to the local market and great quantities were used in agriculture. The mill would sell retail in any quantity. There are endless chicken houses, barns, fences, and homes made with Sturgeon lumber.

This mill ran with a crew of 10 and could cut 15,000 feet of lumber per day. Eventually, the mill’s technology could not compete. The big circle saws cut a 1/3 inch kerf which lost a lot of lumber to sawdust. The newer technology of band sawing (as early as 1914) was faster and cut a much thinner kerf. The mill closed in 1964 and Jim Henningsen passed his interest in the mill to his son Harvey. Ralph Sturgeon passed his interest to his son Bob Sturgeon and daughter Essie Doty.

In 1992 a group of seven former mill workers and historians formed the core of the Sturgeon’s Mill Restoration Project each throwing in a $100 bill and a pledge to save this steam-powered sawmill. The group found traction and more volunteers joined the restoration effort.

In order to obtain a 501(c)(3) non-profit status; Bob, Essie, and Harvey turned over their interest in the sawmill to the Sturgeon’s Mill Restoration Project corporation. This non-profit corporation is dedicated to the restoration of the mill as a working museum.

Bob, Essie, and Harvey grew up around this mill and know the mechanics and workflow. They have dedicated themselves to restoring Sturgeon’s Mill so that others might experience a true slice of early 20th-century technology, commerce, and work ethic. The restoration crew feels honored to preserve this historic mill as an anchor to our industrial past and we invite you to step back in time with us.

Today our working museum’s volunteer crew has grown from the original 7 to over 60 dedicated historians, craftsmen, and women who not only operate the equipment and explain the histories of the mill and its machines but work at restoring the equipment and the mill itself on the first Saturday of every month.

Along with the historical artifacts at the mill, our most valuable asset is our dedicated volunteer crew.